IBS® – Innovative abrasive belts with a revolutionary patented backing

LBA is proud to present the revolutionary range of products branded IBS® (Innovative Backing System®): a new generation of abrasive belts, based on a patented system consisting of a PET film backing, together with velour or paper, combined with high tech abrasive minerals with self-sharpening properties and cooling additives.

The PET film allows the abrasive belt to bear strains caused by working pressure, with no deformations and without compromising sanding results.

Moreover, thanks to the climate stability of the PET film, the belt remains perfectly flat at any level of humidity. The homogeneous coating and the tenacious bonding of the abrasive grains, together with the absence of over-thickness in the joint of the belt reduce the sanding imperfections typical of a traditional abrasive belt.

The high tech abrasive minerals with self-sharpening properties – like Zirconium or Ceramic – and the cooling additives that withstand clogging and prevent the risk of scorch marks, also in case of heavy duty wood processing applications.

The consequence of this advanced mix is a homogeneous sanding pattern, with constant coarseness and a finishing quality you’ve never seen before, even on the most delicate surfaces, and with long life performance!

Read more about the IBS® range!

LBA Taylor Made – The importance of a proper sanding cycle

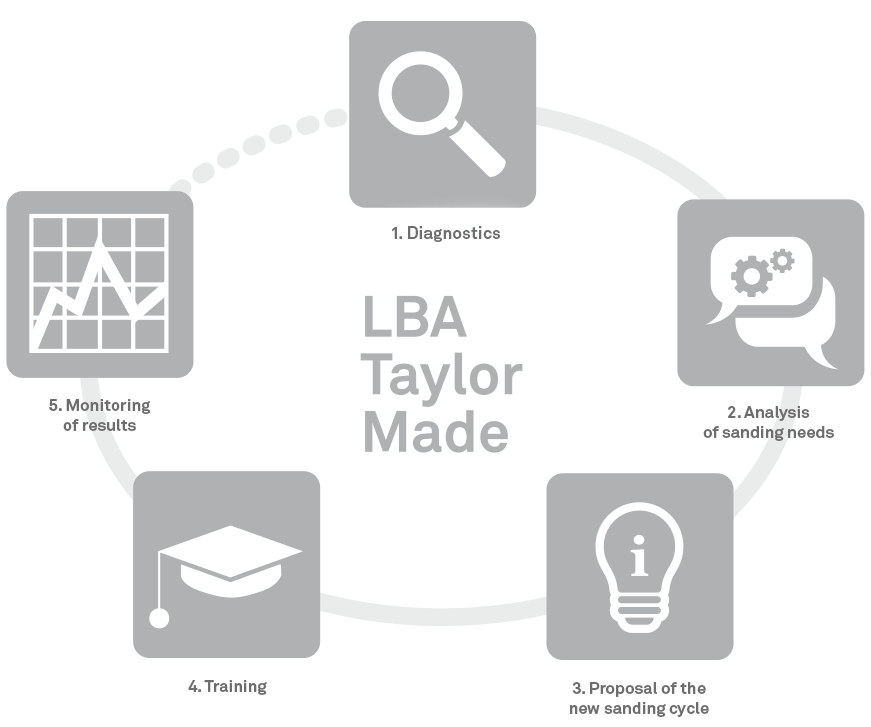

LBA strongly believes that the effectiveness of a proper sanding cycle depends not only on the choice of the most suitable abrasive product, but rather is the result of a more complex system of actions based on a new interaction between customer and supplier, that are continuously sharing their know-how.

For this reason we are proud to present the innovative service LBA Taylor Made, an improving process based on a fluid collaboration between customer and supplier with the aim of identifying the most proper sanding cycle, designed specifically and totally customized, like a tailored suit measured on the customer’s needs.

This service is composed by 5 steps:

at first we have a phase of overall diagnostic of the current manufacturing cycle, ranging from the items to be sanded up to the coating products used, passing through the productive technologies available in the production plant.

The next step is the analysis of the customer’s finishing needs, considering the main trends of the market or the new finishes proposed by our laboratory Finishing Lab.

The third step relates to the formulation of the proposal of the new sanding cycle that is shared with the customer and is put into practice during a test phase with the help of technicians and with a subsequent verification of the results achieved.

When the cycle is completed an important training phase begins with all the people involved in the production process, starting with a basic course about coated abrasives that can be deepened with special “on demand” trainings structured according to the customer’s needs.

Finally LBA decides with the customer some moments of confrontation to safeguard the improvement process, by monitoring results and providing eventual corrections.

Taylor Made service is available for customers always seeking for production improvement.

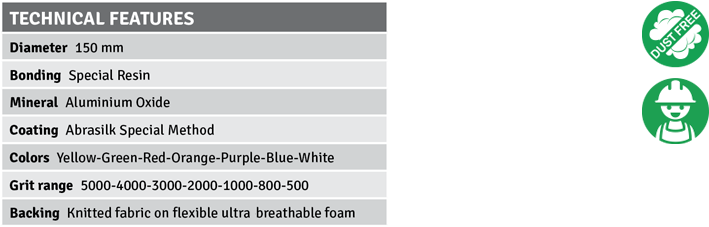

AbraSilk soft – Soft abrasive disks with a revolutionary ultra breathable backing

AbraSilk soft is the new velour abrasive disk with a revolutionary backing composed by fabric laminated with ultra breathable flexible foam. The ultra breathable weave, result of an innovative patented process, allows total dust vacuuming, fostering a better work environment. Transpiration also decreases sanding temperature and enhances resistance to clogging ensuring a longer lifespan and a finishing quality without comparisons. Specific for paint mattening and blending, AbraSilk soft is ideal for homogeneous surface preparation to polishing, to be used both dry and wet.

Applications

• Automotive

• Decoration

• Wood

• Metal

• Composites

• Aerospace & Marine Industry

Suitable Materials

• Wood and derivatives

• Non ferrous metals

• Copper alloys/brass/bronze

• Mild steel

• Carbon steel

• Stainless steel

• Glass fibre

• Aluminium

• Body fillers

• Primers

• Lacquers

• Acrylic resins

• Solid surface

• Plastic materials

Wanna receive more info or plan a test? Just ask!

FINISHING LAB – Innovative abrasive belts for new amazing finishes

LBA presents FINISHING LAB, an experimental laboratory made possible by the collaboration between LBA, the major producers of sanding machines and the italian research institute CATAS, united by the aim of creating innovative finishes for the wood/furniture industry that could be achievable trough simple and easily implementable – both on the economic and on the technological side – production processes, which are characterized by the use of special abrasive belts with standard automatic sanding machines.

Among the successes of FINISHING LAB, there are four innovative finishes that have already various applications in the production of wooden floors and pre-finished parquets, doors for kitchen, living room and bathroom.

The saw effect, the pickled effect, the skyved effect and the scratched effect.

Read more about these surprising finishes