LBA Taylor Made – The importance of a proper sanding cycle

LBA strongly believes that the effectiveness of a proper sanding cycle depends not only on the choice of the most suitable abrasive product, but rather is the result of a more complex system of actions based on a new interaction between customer and supplier, that are continuously sharing their know-how.

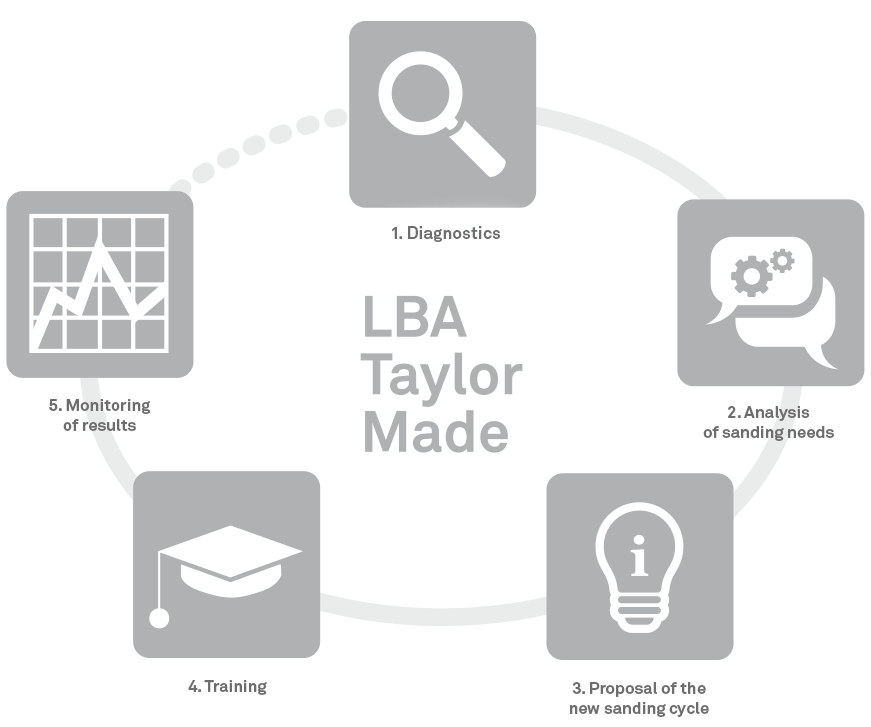

For this reason we are proud to present the innovative service LBA Taylor Made, an improving process based on a fluid collaboration between customer and supplier with the aim of identifying the most proper sanding cycle, designed specifically and totally customized, like a tailored suit measured on the customer’s needs.

This service is composed by 5 steps:

at first we have a phase of overall diagnostic of the current manufacturing cycle, ranging from the items to be sanded up to the coating products used, passing through the productive technologies available in the production plant.

The next step is the analysis of the customer’s finishing needs, considering the main trends of the market or the new finishes proposed by our laboratory Finishing Lab.

The third step relates to the formulation of the proposal of the new sanding cycle that is shared with the customer and is put into practice during a test phase with the help of technicians and with a subsequent verification of the results achieved.

When the cycle is completed an important training phase begins with all the people involved in the production process, starting with a basic course about coated abrasives that can be deepened with special “on demand” trainings structured according to the customer’s needs.

Finally LBA decides with the customer some moments of confrontation to safeguard the improvement process, by monitoring results and providing eventual corrections.

Taylor Made service is available for customers always seeking for production improvement.

Categories: What's New?